Rapid Prototyping Manufacturers in China: A Gateway to Advanced Manufacturing

Rapid prototyping has emerged as a game-changing process in the manufacturing industry, enabling companies to innovate and bring new products to market faster than ever before. As a leader in contract manufacturing, China has positioned itself at the forefront of this technological revolution. In this article, we will explore the role of rapid prototyping manufacturers in China, the advantages they offer, and how they are reshaping the landscape of modern manufacturing.

Understanding Rapid Prototyping

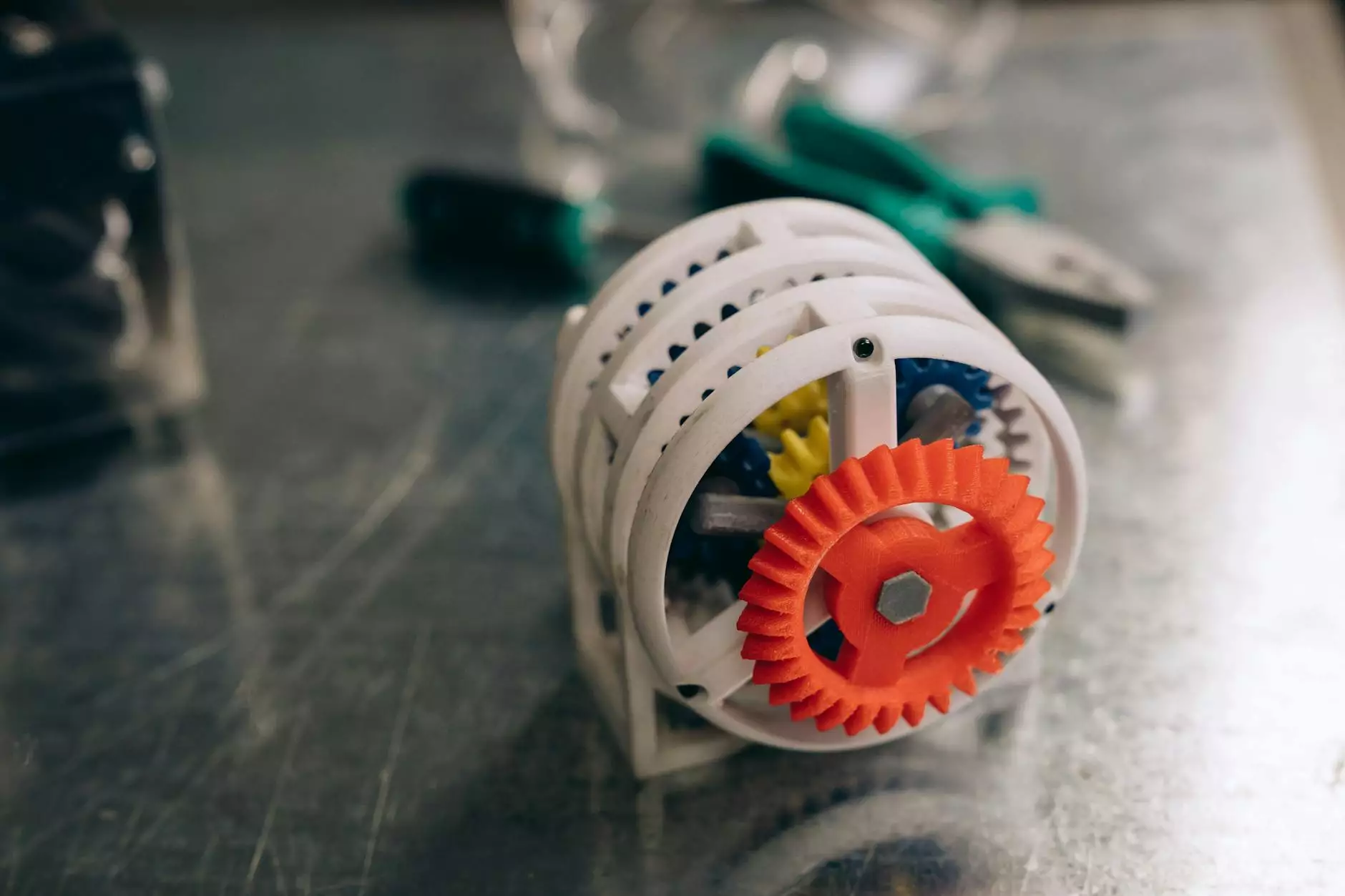

Rapid prototyping is a technique used to quickly fabricate a physical part or assembly using three-dimensional computer-aided design (CAD) data. This process encompasses various technologies, including:

- 3D Printing: Building parts layer by layer using materials like plastic, metal, or resin.

- Stereolithography (SLA): A 3D printing process that uses a laser to cure liquid resin into hardened plastic.

- Selective Laser Sintering (SLS): A technology that uses lasers to fuse powdered materials into solid structures.

- CNC Machining: A subtractive process that removes material from a solid block to create the desired shape.

The Rise of China's Prototyping Industry

China has rapidly become a major player in the realm of rapid prototyping manufacturing. This transformation can be attributed to several key factors:

1. Technological Advancements

Chinese manufacturers have embraced cutting-edge technologies and have continually invested in the latest machinery and software, allowing them to offer a wide range of prototyping solutions.

2. Cost Efficiency

China's manufacturing sector benefits from lower labor costs compared to Western countries. This cost advantage allows rapid prototyping manufacturers in China to offer competitive pricing without sacrificing quality.

3. Skilled Workforce

With an abundance of engineering and technical talent, China has cultivated a skilled workforce adept in modern manufacturing techniques, including rapid prototyping.

4. Infrastructure Development

China has heavily invested in its manufacturing infrastructure, including logistics, transportation, and supply chain management, facilitating the efficient production and delivery of prototypes.

The Advantages of Working with Rapid Prototyping Manufacturers in China

Choosing to collaborate with rapid prototyping manufacturers in China comes with numerous benefits:

1. Speed to Market

One of the most significant advantages is the ability to bring products to market rapidly. This speed enables companies to test new ideas, gather feedback, and make necessary improvements quickly.

2. Customization and Flexibility

China’s manufacturers offer a high degree of customization, allowing clients to create prototypes tailored to their specifications without lengthy design cycles.

3. High Quality Standards

Many rapid prototyping manufacturers in China adhere to international quality standards, ensuring that prototypes meet the necessary requirements for functionality and durability.

4. Comprehensive Services

These manufacturers often provide end-to-end solutions, from design and engineering to production and finishing. This holistic approach simplifies the process for companies seeking to develop new products.

Key Industries Benefiting from Rapid Prototyping in China

Various industries have significantly benefited from the services of rapid prototyping manufacturers in China:

1. Automotive

The automotive industry relies on rapid prototyping for designing complex parts and testing before mass production, significantly reducing development times.

2. Aerospace

In aerospace, precision and reliability are critical. Rapid prototyping allows for the creation of lightweight components that must meet stringent regulatory standards.

3. Medical Devices

Medical technology companies leverage rapid prototyping to develop innovative devices that improve patient outcomes, allowing for rapid testing and iteration.

4. Consumer Electronics

The fast-paced nature of the consumer electronics market makes prototyping essential for testing new features and designs quickly.

Finding the Right Rapid Prototyping Manufacturer in China

When seeking a reliable partner in rapid prototyping, consider the following factors:

1. Experience and Reputation

Look for manufacturers with a proven track record and positive customer reviews in the prototyping space. Their experience can significantly influence your project's success.

2. Technology and Equipment

Evaluate the technology and equipment used by the manufacturer. Advanced equipment often translates to better quality and faster turnaround times.

3. Communication and Support

Effective communication is crucial. Ensure that the manufacturer has robust support systems and can communicate clearly throughout the project.

4. Scalability

Choose a manufacturer that can scale up production as your needs grow, ensuring they can accommodate both small runs and large-scale production.

Quality Assurance in Rapid Prototyping

Quality assurance is paramount in the prototyping process. Reputable rapid prototyping manufacturers in China implement various quality control measures, including:

- Regular Equipment Calibration: Ensuring that all machines operate at optimal performance.

- Material Testing: Conducting thorough tests on raw materials to verify they meet required specifications.

- Process Audits: Carrying out regular audits to assess and improve production processes.

- Final Inspection: Performing exhaustive inspections of prototypes before delivery to ensure they meet quality standards.

The Future of Rapid Prototyping in China

The future of rapid prototyping manufacturers in China looks promising, with advancements in technology and a growing demand for fast, high-quality prototyping solutions. Emerging trends include:

1. Integration of AI and Machine Learning

With the integration of artificial intelligence and machine learning, manufacturers can optimize design processes, predict potential failures, and reduce lead times.

2. Sustainability Practices

With increasing focus on sustainability, manufacturers are exploring eco-friendly materials and processes, striving to reduce waste and environmental impact.

3. Expanded Material Options

As the field advances, manufacturers are continuously researching and developing new materials to enhance the performance and application of prototypes.

4. Global Collaboration

In an increasingly interconnected world, global collaboration will flourish, enabling manufacturers to leverage different expertise and technologies from around the world.

Conclusion

Choosing the right partner among rapid prototyping manufacturers in China can significantly enhance your product development process. With their expertise and advanced technologies, they open doors to innovation, speed, and efficiency in manufacturing. As businesses continue to strive for competitive advantages in today's fast-paced market, the importance of rapid prototyping as an invaluable tool will only grow. By understanding the dynamics of this industry and leveraging the capabilities of Chinese manufacturers, companies can pave their way to success and sustainable growth.

For more information on high-quality rapid prototyping services, visit DeepMould.

rapid prototyping manufacturers china