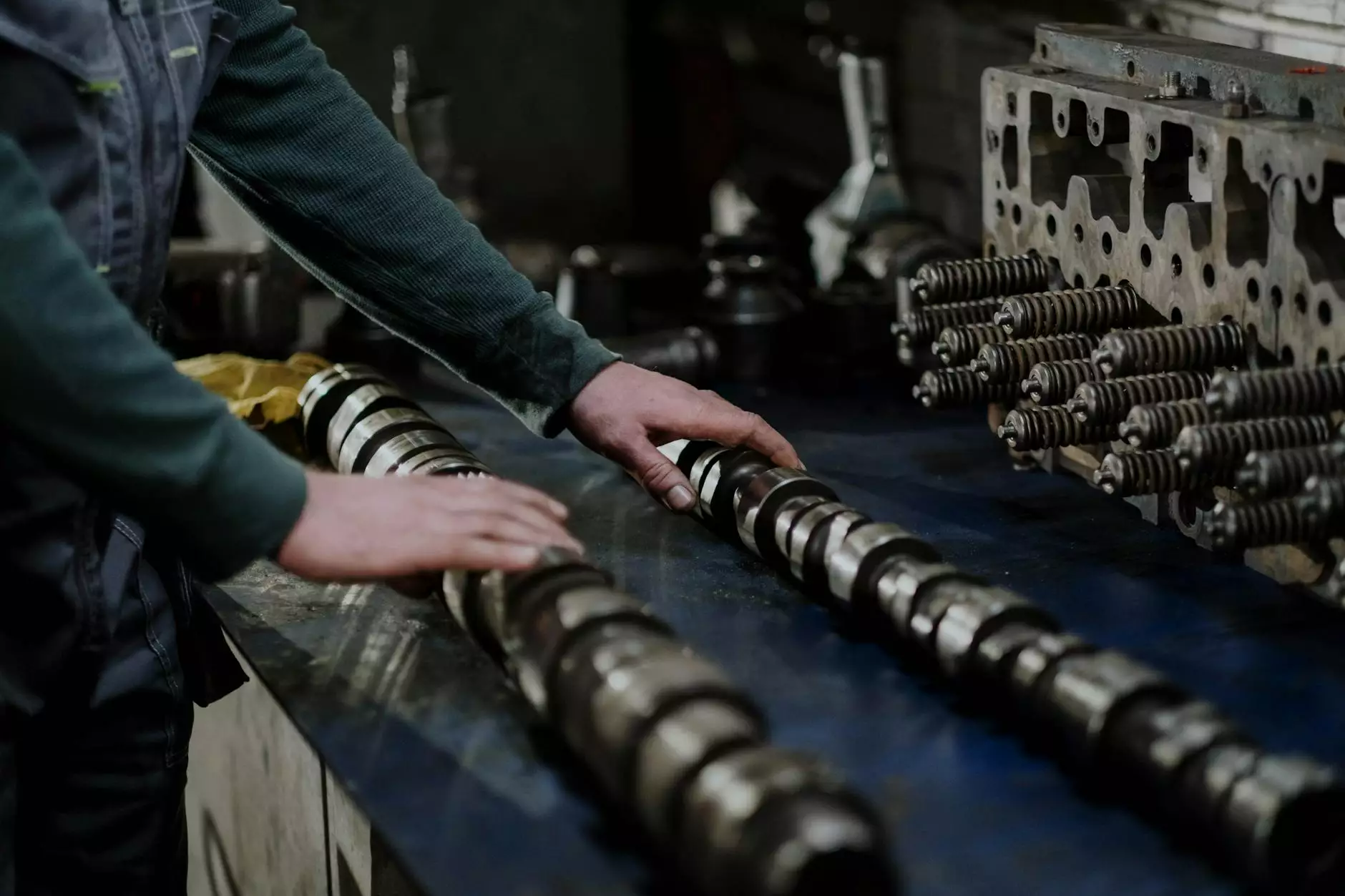

Understanding the Role of a Camshaft Manufacturer in Diesel Engine Parts

The camshaft is a critical component in any engine, playing a pivotal role in the functionality and performance of diesel engines. As a camshaft manufacturer, our commitment goes beyond merely supplying parts; it's about ensuring that our products meet the highest standards in performance and durability. At client-diesel.com, we specialize in providing top-quality diesel engine parts and are recognized as leaders among spare parts suppliers.

What is a Camshaft and Why is it Important?

The camshaft is responsible for controlling the timing of the engine's valves. In simple terms, it ensures that the right amount of air and fuel enters the combustion chamber at the appropriate times. A well-designed camshaft contributes directly to engine efficiency, power output, and emissions control.

Types of Camshafts

- Overhead Camshaft (OHC): Present in modern engines, allowing for more precise control of valve timing.

- Single Overhead Camshaft (SOHC): Features one camshaft per bank of cylinders.

- Double Overhead Camshaft (DOHC): Contains two camshafts per bank, enhancing engine performance and efficiency.

- Pushrod Camshaft: Commonly used in older engines, utilizing pushrods to operate the valves.

The Manufacturing Process of Camshafts

As a dedicated camshaft manufacturer, we employ advanced techniques to ensure our products stand out in the competitive market. Here’s a breakdown of our manufacturing process:

1. Material Selection

The first step involves selecting top-grade materials that can withstand high levels of stress and temperature. Common materials include:

- Cast Iron: Known for its durability and cost-effectiveness.

- Alloy Steel: Offers enhanced strength for high-performance applications.

- Aluminum: Lightweight yet strong, suitable for applications requiring weight savings.

2. Precision Machining

Once the materials are selected, the next step is precision machining. Using cutting-edge CNC machines, we achieve exact specifications for each camshaft. This process involves:

- Turning: Shaping the camshaft body.

- Milling: Cutting complex profiles of the cam lobes.

- Grinding: Achieving ultra-smooth surfaces for optimal performance.

3. Heat Treatment

After machining, the camshafts undergo heat treatment. This critical process enhances hardness and wear resistance, ensuring longevity and reliability in all applications.

4. Quality Control

Every camshaft produced at client-diesel.com is subjected to stringent quality control measures. We assess each product for:

- Dimensional accuracy: Ensuring that each part fits perfectly within the engine specifications.

- Surface finish: Confirming that the camshaft can minimize wear and friction.

- Functional testing: Verifying the performance characteristics meet industry standards.

Why Choose client-diesel.com as Your Camshaft Manufacturer?

Choosing the right camshaft manufacturer is crucial for the success of your diesel engine projects. Here’s why client-diesel.com stands out:

Quality Assurance

We are dedicated to providing only the highest quality products. Our rigorous testing protocols ensure that every camshaft meets the demanding standards of the diesel engine industry.

Innovation and Technology

Our investment in state-of-the-art technology allows us to stay ahead of the competition. We continuously refine our processes and innovate our product offerings to meet the evolving needs of our clients.

Customer-Centric Approach

At client-diesel.com, customer satisfaction is our top priority. We work closely with our clients to understand their specific needs and offer tailored solutions.

Comprehensive Product Range

As a leading spare parts supplier, we offer a comprehensive range of diesel engine parts, including but not limited to:

- Camshafts

- Cylinders

- Pistons

- Fuel injection pumps

- Turbochargers

The Importance of Proper Camshaft Maintenance

Choosing the right camshaft is just the beginning. Proper maintenance is essential to ensure longevity and performance. Here are some key maintenance tips:

1. Regular Inspections

Conduct routine inspections to check for signs of wear, scoring, or damage. Early detection can prevent more significant issues down the road.

2. Proper Lubrication

Ensure that the camshaft is well-lubricated to minimize friction and wear. Use high-quality engine oil recommended by the manufacturer.

3. Follow Manufacturer Guidelines

Adhere strictly to the maintenance guidelines provided by your engine manufacturer to optimize performance and extend the lifespan of the camshaft.

Environmental Considerations in Camshaft Manufacturing

As a responsible camshaft manufacturer, we recognize the importance of sustainable practices. We are committed to reducing our environmental impact through:

1. Efficient Resource Use

We aim to minimize waste and ensure that resources are utilized effectively throughout our manufacturing processes.

2. Eco-Friendly Materials

Whenever possible, we source materials that are environmentally friendly and recyclable, contributing to a more sustainable manufacturing chain.

3. Compliance with Environmental Regulations

We strictly adhere to all environmental regulations and standards to ensure that our operations are in line with best practices for sustainability.

Conclusion: Trustworthy Camshaft Manufacturer

In conclusion, your choice of a camshaft manufacturer can significantly impact your engine's performance and reliability. At client-diesel.com, we pride ourselves on our dedication to quality, innovation, and customer satisfaction. Whether you need parts for maintenance or high-performance applications, we are here to provide you with the best solutions tailored to your requirements. Join our long list of satisfied clients who trust us for their diesel engine parts and experience the difference today!